Luɔi karen:

1200mm HDPE tubing production line ee tubing production equipment. HDPE pipes ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni ye dɔɔni

Fɛɛr:

● Luɔi dɔ̈ŋ, luɔi dɔ̈ŋ.

● PLC automatic control system ku HMI touch screen control panel.

● Ajuiɛɛr ye tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ.

• Metre weight system.

● Luɔi de spiral mould structure design ye kɔrɔ.

● Traktor ye servo motor drive, speed adjustment range ye dɔɔni, stability ye dɔɔni. A tɛmɛ lifter ye, a nɔgɔya ka tubu ye tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u ka tɔ̈ɔ̈u.

● Masin ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye kɛ̈ɛ̈r ye k

● A tɛ̈n tɔ̈u, a tɛ̈n tɔ̈u.

Equipment Composition:

Single screw extruder + co-extruder + tube mould + vacuum diameter box + cooling spray box + six claw track tractor + chipless cutting machine +Lifting rackYe.

Parameters teknis:

|

Host |

|||||||||

|

Extruder |

Model |

Kɛnɛya |

Puwol host |

Speed |

Luɔi (kg/h) |

||||

|

Single screw extruder |

SJ-120/38 |

38:1 |

355kw |

94rpm |

1100-1200 |

||||

|

Ajuiɛɛr (630-1200mm) |

|||||||||

|

Vacuum diameter box 1 ye |

Spray cooling box 2 ye |

Cutting Machine |

Cutting Machine |

Lifting rack 2 ye |

|||||

|

Dɔŋ: 12000mm |

Dɔŋ: 6000mm |

12 claw track |

Cutting without chips |

Dɔŋ: 4000mm |

|||||

|

Pump: 5.5kw * 6 set |

Pump: 7.5kw * 2 set |

Servo motor 0.85kw * 12 set |

Kɔɔr: 7.5kw |

||||||

|

Pump: 7.5kw * 6 set |

0-0.5 m/min |

||||||||

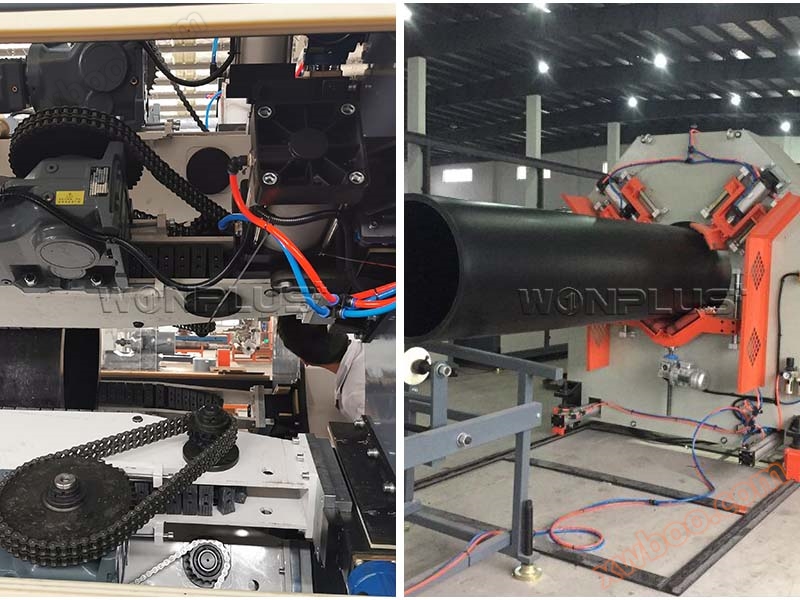

Image introduction of extruder production line: