Član VIP

Q345B pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip pip

Q345B ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n ye tɛ̈n

Detalji proizvoda

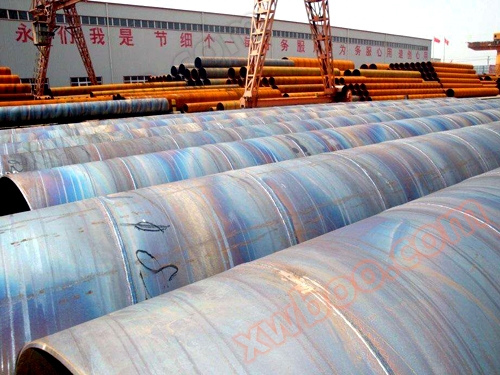

Q345B kalibre fitinSpiral Steel PipeKä ye kek looi aye Q345B, Q345 ye kek looi. A ye carbon low alloy steel (c<0.2%), a ye baara kɛ ka ɲi, a ye baara kɛ ka ɲi, a ye baara kɛ ka ɲi, a ye baara kɛ ka ɲi, a ye baara kɛ ka ɲi, a ye baara kɛ ka ɲi, a ye baara kɛ ka ɲi, a ye baara kɛ ka ɲi. A be tɔ̈u në bridge, motɛr, koom, ɣööt, pressure containers, etc. Q ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ̈l ye kɛ A bɛ kɛ̈ɛ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r ye dɔ̈ɔ̈r.

Q345B ye tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈

Q345B tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈n tɛ̈

Q345B tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yenë tɛ̈n yen Lɔ̈ɔ̈m ye kɔɔr: Pii, pii. Gas: Gas, steam, liquefied petroleum gas. Luɔ̈ɔ̈i: Luɔ̈ɔ̈i pip, luɔ̈ɔ̈i bridge; Docks, roads, building structures tubes and so forth.

Q345B Small Caliber Spiral Steel Pipe Production Process

1.Raw materials ye steel roll, welding wire, welding agent. Ka tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ tɛmɛ A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

2.With steel head and tail docking, using single wire or dual wire buried arc welding, after rolling into steel tubes, using automatic buried arc welding after rolling into steel tubes. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

3.Before forming, steel after straightening, cutting edge, planer edge, surface cleaning conveying and bending edge treatment. 3.Before forming, steel after straightening, cutting edge, planer edge, surface cleaning conveying and bending edge treatment. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

4. Lɔ̈ɔ̈m de electric contact pressure meter ye kɔc cɔl conveyor ye kɔc cɔl cylinder ye kɔc cɔl cylinder ye kɔc cɔl cylinder ye kɔc cɔl cylinder ye kɔc cɔl cylinder ye kɔc cɔl cylinder. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

5. Luɔ̈ɔ̈i ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan ye raan. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

6.Use welding gap control device to ensure welding gap meets welding requirements, tube diameter, fault edge quantity and welding gap are all strictly controlled. 6.Use welding gap control device to ensure welding gap meets welding requirements, tube diameter, fault edge quantity and welding gap are all strictly controlled. 7.Inside welding and outer welding are used by American Lincoln wire welding machine for single wire or dual wire buried arc welding, so as to get a stable welding specifications. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

8. Welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded welded Na cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye cïn kë ye c A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

9.Use air plasma cutting machine to cut steel tubes into single roots. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

10.After cutting into a single steel pipe, each batch of steel pipes must be carried out a strict first inspection system, checking the mechanical properties of welded seams, chemical composition, melting condition, steel pipe surface quality and after a non-destructive detection and injury inspection, to ensure that the manufacturing process is qualified, before being officially put into production. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

11.The welding seam has a continuous sonic wave detection mark on the part, after manual ultrasonic and X-ray inspection, if there is indeed a defect, after repairing, again after non-destructive inspection, until the defect has been eliminated. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

12. A tɛ̈n yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen yen A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

13.Each steel tube is tested after hydrostatic pressure, pressure is used radial sealing. 13.Each steel tube is tested after hydrostatic pressure, pressure is used radial sealing. 13.Each steel tube is tested after hydrostatic pressure, pressure is used radial sealing. Tɛ̈ɛ̈r de tɛ̈ɛ̈r de tɛ̈ɛ̈r de tɛ̈ɛ̈r de tɛ̈ɛ̈r de tɛ̈ɛ̈r Test parameters prints logs automatically. A ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye kɔc cɔl a ye

14. Pipe end machining, ka end face verticality, slope angle and blunt edges be kɔnɔna cɛ̈ɛ̈k.

Онлайн разпит